ZOOMLION has recently been recognized in the “Hunan Top 10 Science and Technology News 2025,” as its Excavator Shared Manufacturing Intelligent Factory was selected into China’s first batch of Lighthouse Intelligent Factory cultivation projects. As the only enterprise from Hunan Province included in this national list, ZOOMLION has set a benchmark for high-end equipment manufacturing by introducing an innovative “shared manufacturing” model that can be replicated and promoted across the industry.

The Lighthouse Intelligent Factory represents the highest level in China’s intelligent manufacturing development system. It is jointly promoted and certified by six national ministries, including the Ministry of Industry and Information Technology, and reflects the future direction of smart manufacturing in China. In November 2025, at the World Intelligent Manufacturing Conference, the first batch of selected enterprises was officially announced, with only 15 companies nationwide making the list. ZOOMLION successfully broke through the world-class challenge of mixed-flow production for heavy equipment characterized by multiple models and small batch sizes, and built a globally unique collaborative and shared intelligent factory cluster for construction machinery.

The ZOOMLION Excavator Shared Manufacturing Intelligent Factory has realized full-process intelligent manufacturing across six core production stages, enabling more than 100 excavator models to be efficiently produced on shared mixed-flow lines. It has also pioneered a new collaborative production model linking excavators with cranes, concrete pump trucks, and aerial work platforms, significantly improving overall manufacturing efficiency. As a result, steel plate material utilization has exceeded 90%, and work-in-process inventory for structural parts has been reduced by 70%, fundamentally solving one of the long-standing production challenges in the construction machinery industry.

“Sharing” is the core concept behind this intelligent factory. By horizontally covering four major categories of construction machinery and vertically connecting hundreds of production processes, ZOOMLION has built a highly integrated collaborative manufacturing ecosystem. Supported by self-developed AI dynamic resource scheduling algorithms and multi-modal flexible workstations, the production lines can achieve zero-changeover between different models, allowing production resources to self-organize and self-optimize. With an overall automation rate of 85% and six unmanned “black-light” production lines, the factory can produce one excavator every six minutes on average. From steel plate cutting to complete machine rollout, the entire manufacturing cycle takes only 6.5 days, while customized products can be delivered to domestic customers in as fast as two weeks.

These achievements have set new global benchmarks in production pace, changeover time, and manufacturing cycle in the construction machinery industry. Looking ahead, ZOOMLION will continue to promote the deep integration of next-generation artificial intelligence and robotics, explore new models of future manufacturing, and provide more “China Smart Manufacturing” solutions to support global industrial upgrading. As an important practitioner of Hunan’s development strategy, ZOOMLION will continue to drive high-quality growth in China’s high-end equipment manufacturing sector through technological innovation.

-

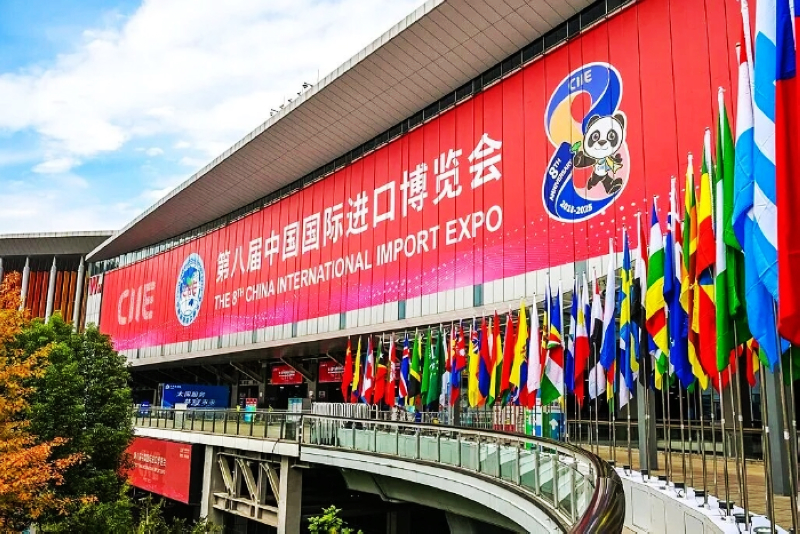

2026-01-16 XCMG Showcases Smart Manufacturing at CIIE 2025On November 10, the 8th China International Import Expo (CIIE) successfully concluded in Shanghai. As the first major diplomatic and economic event hosted by China following the 20th CPC Central Committee’s Fourth Plenary Session, this year’s CIIE brought together 155 countries, regions, and international organizations, with more than 4,100 overseas enterprises participating — setting a new record in scale and global influence.View More

2026-01-16 XCMG Showcases Smart Manufacturing at CIIE 2025On November 10, the 8th China International Import Expo (CIIE) successfully concluded in Shanghai. As the first major diplomatic and economic event hosted by China following the 20th CPC Central Committee’s Fourth Plenary Session, this year’s CIIE brought together 155 countries, regions, and international organizations, with more than 4,100 overseas enterprises participating — setting a new record in scale and global influence.View More

-

2026-01-16 LIUGONG 8100TE Hybrid Wheel Loaders Delivered to Port ClientRecently, LIUGONG successfully delivered the first batch of 8100TE large hybrid wheel loaders to a major port industry client. As a long-term strategic partner, this large international port in northern China has already purchased nearly 100 LIUGONG machines, including large wheel loaders and excavators. The addition of the 8100TE model will further enhance its leading edge in green, efficient, and sustainable operations.View More

2026-01-16 LIUGONG 8100TE Hybrid Wheel Loaders Delivered to Port ClientRecently, LIUGONG successfully delivered the first batch of 8100TE large hybrid wheel loaders to a major port industry client. As a long-term strategic partner, this large international port in northern China has already purchased nearly 100 LIUGONG machines, including large wheel loaders and excavators. The addition of the 8100TE model will further enhance its leading edge in green, efficient, and sustainable operations.View More

-

2026-01-16 SANY Showcases at CICEE Southeast Asia Exhibition in MalaysiaOn September 4, 2025, the 3rd Changsha International Construction Equipment Exhibition (CICEE) Southeast Asia Edition opened at the Setia City Convention Centre in Kuala Lumpur, Malaysia. The exhibition was inaugurated by Zhang Yingchun, Executive Vice Governor of Hunan Province.View More

2026-01-16 SANY Showcases at CICEE Southeast Asia Exhibition in MalaysiaOn September 4, 2025, the 3rd Changsha International Construction Equipment Exhibition (CICEE) Southeast Asia Edition opened at the Setia City Convention Centre in Kuala Lumpur, Malaysia. The exhibition was inaugurated by Zhang Yingchun, Executive Vice Governor of Hunan Province.View More

-

2026-01-16 ZOOMLION Opens Bulacan Warehouse Center in the PhilippinesRecently, the opening ceremony of the ZOOMLION Bulacan Warehouse Center was held in Bulacan Province, Philippines. Following its inauguration, this site has become ZOOMLION’s largest outlet in the Philippines and is designated as one of its main warehouses. It will mainly be responsible for the storage, distribution, and service of products and spare parts, supporting sales and after-sales operations in the local and surrounding areas.View More

2026-01-16 ZOOMLION Opens Bulacan Warehouse Center in the PhilippinesRecently, the opening ceremony of the ZOOMLION Bulacan Warehouse Center was held in Bulacan Province, Philippines. Following its inauguration, this site has become ZOOMLION’s largest outlet in the Philippines and is designated as one of its main warehouses. It will mainly be responsible for the storage, distribution, and service of products and spare parts, supporting sales and after-sales operations in the local and surrounding areas.View More

-

2026-01-16 HANGCHA Holds 2025 Europe Product & Sales Training in FranceFrom June 17 to 20 local time, HANGCHA Group successfully held its 2025 Europe Product and Sales Training event at the HANGCHA Europe Rental Company in Senlis, France. The event attracted core dealer partners from across Europe and Africa, with some participants traveling over 6,000 km to attend in person.View More

2026-01-16 HANGCHA Holds 2025 Europe Product & Sales Training in FranceFrom June 17 to 20 local time, HANGCHA Group successfully held its 2025 Europe Product and Sales Training event at the HANGCHA Europe Rental Company in Senlis, France. The event attracted core dealer partners from across Europe and Africa, with some participants traveling over 6,000 km to attend in person.View More

-

2026-01-16 Significant Progress Achieved in Multiple Key Overseas Projects by CRCHICurrently, CRCHI is striving toward its annual targets with full commitment and practical efforts, achieving remarkable progress in several overseas engineering projects.View More

2026-01-16 Significant Progress Achieved in Multiple Key Overseas Projects by CRCHICurrently, CRCHI is striving toward its annual targets with full commitment and practical efforts, achieving remarkable progress in several overseas engineering projects.View More

-

2026-01-16 Building a Dream World of Ice and Snow, XCMG Helps Winter MiraclesThe 9th Asian Winter Games (hereinafter referred to as the "Asian Winter Games") kicked off in Harbin! This ice and snow event is not only a grand event for winter sports enthusiasts, but also a stage for companies from all over the country to showcase their product strengths. XCMG must also shine here!View More

2026-01-16 Building a Dream World of Ice and Snow, XCMG Helps Winter MiraclesThe 9th Asian Winter Games (hereinafter referred to as the "Asian Winter Games") kicked off in Harbin! This ice and snow event is not only a grand event for winter sports enthusiasts, but also a stage for companies from all over the country to showcase their product strengths. XCMG must also shine here!View More